Granite’s durability, abrasion resistance, and beauty make it a popular countertop material. Success in the granite fabrication industry relies on the fabricator’s experience and tools. Find out more about the essential tools that granite fabricators use for countertops.

Fabricators use transport racks to handle large, heavy slabs of granite. These racks can hold one or more slabs at a time and enable fabricators to transport and store slabs safely and efficiently. Rubber padding protects the granite’s surface from rubbing against the rack. While it takes more than transport racks to handle granite, they are an essential tool used in the process. Diamond Floor Polishing Pads For Concrete

Stonecutting saws are an essential tool granite fabricators use to transform slabs into countertops. Stonecutters use an array of saws to achieve different cuts, including circular saws, angle grinders, and miter saws equipped with diamond saw blades.

Stonecutters use their tools for large cuts that bring the slab to the right size and for more meticulous cuts that give the countertop its shape. They can use wet or dry cutting techniques to achieve their desired results. The stonecutters’ array of saws, expertise in making precise cuts, and familiarity with the challenging stonecutting process make granite countertops an involved project best left to professionals.

When it comes to creating the edge profile of a granite countertop, stone routers simplify the process. Fabricators use stone routers to create edges in different designs, including straight, round, waterfall, and bevel. The stone router fitted with a router bit allows the fabricator to shape the edge quickly and easily. After this process, the fabricator smooths the edge to prepare it for polishing.

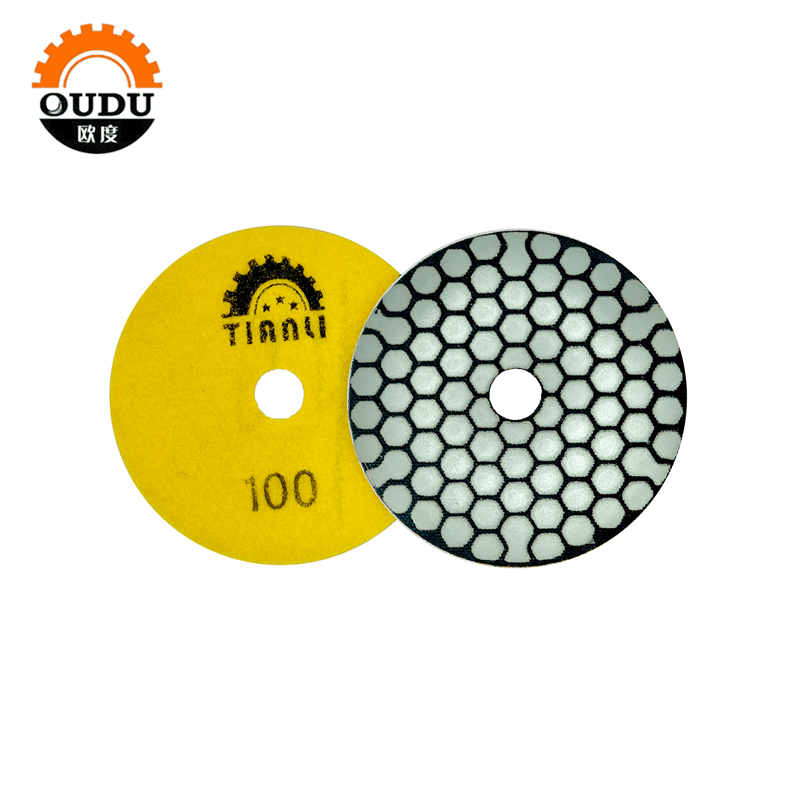

Concrete Buffing Pads Along with polishing machines and backer pads, fabricators use polishing pads to polish granite and other stones. The type of pad the fabricator uses depends on whether they’re using a wet or dry polishing technique. They also consider the size of the pad; a larger pad can polish a larger area, but a smaller pad can reach more difficult spaces. Flexible polish pads are great for polishing edges, and rigid pads work well on flat surfaces.